Disclaimer

I do not guarantee the accuracy of any of this information. Acting on this information is AT YOUR OWN RISK. Content is provided for Super Safety reference and entertainment only.

Last updated: September 20, 2025

Table of contents

- Overview & scope

- Credits & sources

- General tips (all platforms)

- 9mm blowback notes

- AR-15 specific notes

- Rate of fire references

- Reference links

Overview & scope

This cheat sheet is your ultimate go-to for cool tips and fixes straight from the community for the Hoffman Tactical Push-Button Super Safety—or as we like to call it, “SS” or “Super Safety” for short. It’s jam-packed with all sorts of installation hacks, compatibility info, and troubleshooting tricks that folks have shared from their own experiences. Just a heads up, this guide is all about the Hoffman Push-Button version, unless we say otherwise.

Credits & sources

So very grateful for Blowback 9 for putting together all of this information. I linked his WP page, where you can find a plethora of information on the things we all love, GUNS

Much appreciation to Hoffman Tactical and many community contributors who have documented testing and fixes. Additional community resources and links are included in the References section.

General tips (applies to all platforms)

- Full-auto profile BCG/bolt required. A full-auto profile bolt or carrier (5.56 BCG or equivalent 9mm bolt) is commonly required for reliable SS operation.

- Lubrication: Keep bolt and Super Safety contact points well lubricated. Light gun oil for bolts and grease for SS contact/friction points (automotive bearing grease works well).

- Centering device / washers: A centering device or thin washers on the cam can help keep the lever centered and prevent mis-timing. Examples and part numbers are in the References section.

- Lower shelf clearance: Make sure there’s a low or no shelf behind the safety in the lower part. If the Super Safety lever can’t swing back far enough, just trim the shelf or grab a centering device. (Tip: the lever should rest back on a 1/8″ drill bit laid across the open lower.)

- Cam forces to semi after firing: If the cam forces the system to semi after a round, trim the side points of the shelf behind the cam in the lower or use a centering device to prevent forced rotation.

- Locks up when cam in rear: Commonly caused by upper shelf interference. Solutions: trim upper shelf in front of rear takedown pin lug behind the Super Safety, reduce top-of-lever height, or (AR-15) reduce buffer travel (e.g., temporary quarters in buffer tube to test).

- A little lever wiggle is normal: You want the lever to have about ~6–12° of give moving forward and backward in the cam slot without the cam budging — that little bit of play is actually needed to make it work right.

- Assembly order: Install trigger/disconnector first, then hammer. Hammer spring legs must rest on top of the trigger pin, not underneath.

Trigger & disconnector notes

- Burst on semi pull: Often caused by disconnector spring installed upside down or a weak spring.

- Hard trigger pull: Can be mitigated by trimming a shallow dip (“divot cut”) in the trigger bar just in front of its curved end.

- Semi won’t fire / trigger dead: Consider shaving inside of left trigger bar arm to thin it; check trigger reset and trigger geometry.

AR-15 Super safety specific notes

- AR-15 buffers: Think of the H3 deadblow + standard carbine spring as the bouncer at the club of your AR-15 SS installs, keeping that pesky bolt bounce in check. For some of those fancy AR builds where fashion meets function, the H3/H2 combo with just the right deadblow weight is like bringing a plus one to the party—it’s just better!

- Single-shot behavior: SS will function as single-shot in many AR-15 builds — heavier deadblow buffers may help control timing but can produce other side effects. Use mil-spec hammers when possible.

- Short stroking: If the weapon short strokes (fires/ejects/bolt closes on empty), the buffer or spring may be too heavy; lower the weight or change spring profile accordingly.

Bolt compatibility

Many “Outerwild/White Label” style bolts and IDL OEM bolts are reported to work if rear weight is trimmed correctly. Brands that have been reported in community testing are listed in the References/Appendix

Super Safety 9mm blowback — specific notes

Many of these “scientific discoveries” came from your neighbor’s backyard, so test them responsibly!

BCG & Buffer weight recommendations

- Target ~24–27 oz total bolt + buffer mass for reasonable ROF in many 9mm blowback setups. Standard 9mm deadblow buffers (~22 oz) are a common baseline.

- A recommended starting deadblow buffer: 10–11 oz deadblow. Examples: Palmetto State Armory (11 oz), Stern Defense (11 oz), Kaw Valley Precision (10 oz), Macon Armory (11 oz).

- Pro tip: Use an A5 length buffer tube (7.75″), standard carbine spring and deadblow buffer, and consider adding a spacer weight in the tube to reach desired mass while preserving bolt travel.

- Avoid H2/H3 for 9mm blowback unless you know the setup — many report H2/H3 are too short/light and can cause bolt-catch snaps or premature extraction. Use carbine-length setups and deadblow weights instead.

- Spring strength: Use carbine strength springs (approx. 11–13 lb). Increasing spring strength does not reliably reduce overall bolt cycle speed — it can increase bolt return speed and ROF in some cases.

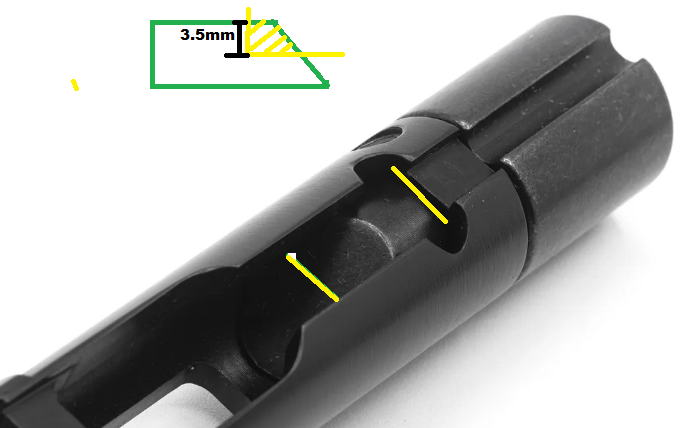

- Trim rear bolt weight: Make sure the rear bolt weight is as flush with the trip surface as your best friend’s excuses on a bad hair day, or even recessed a bit further. We need the FA trip surface to have enough room to breathe—because let’s face it, nobody likes a jam. It’s like trying to squeeze into those jeans after the holidays; you just don’t want that kind of pressure!

Images & diagrams

Hey, check out this NFA 9mm BCG! Just pull that pin like it owes you money to access the BCG weight in the pic on the left. Below, you’ll spot the BCG and Weight before their dramatic separation. Make the cut, reassemble the pieces, and voilà – you’re the proud parent of a reassembled BCG!

- Washer centering examples: Hillman Nylon 3/8 x 0.194 x 1/32 (thin)

- Buffer recommendations (9mm): Palmetto State Armory 11oz deadblow, Stern Defense 11oz, Kaw Valley 10oz

- Possible problem bolts: Some Foxtrot Mike Products or PSA Gen3 have reported light strike concerns; consider firing pin swaps or alternative bolts.

- HT original video — history & how it works

- Video 1

- Video 2

- r/supersafety subreddit (community threads)

- SSCS (Blowback9) — consolidated notes (external)